Productive and Environmentally Friendly Technology for Pond Restoration

Damaged Ponds Are Not Just a Production Issue

Ponds that experience ecological degradation not only lose productivity, but also lose biological homeostasis—the complex balance between microorganisms, plankton, dissolved oxygen, and substrate. When this balance collapses, ponds transform from productive ecosystems into sources of disease, waste, and economic loss.

Ecological damage to ponds is generally triggered by:

- Excessive accumulation of organic matter,

- Phytoplankton blooms (algae blooming),

- Heavy metal contamination and antibiotic residues,

Damage to natural biofilms that serve as water quality buffers.

In this context, conventional approaches based on reactive chemistry are no longer sufficient. Ecosystem biotechnology is the only rational and sustainable path—not just to “fix,” but to heal ponds systemically.

Bioremediation as the Foundation for Pond Ecosystem Restoration

Bioremediation utilizes the natural ability of microorganisms to decompose organic waste, ammonia, nitrite, and other toxic compounds. Umar et al. (2024) in A Review Paper on Bioremediation: A Panacea to Aquaculture Productivity show that the use of a consortium of nitrifying and denitrifying bacteria can increase the efficiency of pond ecosystems by 65–80% within 4–6 weeks.

Key microorganisms that have been proven effective include:

- Nitrosomonas & Nitrobacter for the oxidation of ammonia into nitrate,

- Bacillus subtilis & Pseudomonas putida for the degradation of organic matter,

- Rhodobacter sphaeroides for stabilizing the redox conditions of the pond.

However, the challenge of modern aquaculture is a much higher and faster pollution load, so natural bioremediation needs to be supported by physics-chemistry-based acceleration technology.

Electrolysis and UV: Catalysts for the Aquaculture Biosecurity Revolution

Water electrolysis technology works on an elegant principle: using electrical energy to transform water into a restorative agent for itself. This process produces powerful oxidants such as hypochlorite (HOCl), micro-ozone, and hydroxyl radicals (•OH) that have high oxidative potential without leaving harmful residues.

Ranganathan et al. (2025) in the Journal of Environmental Biotechnology reported that Microbial Electrolysis Cells (MEC) are capable of:

- Reducing COD by 90%,

- Eliminating 95% of aquaculture pathogens,

without the use of synthetic chemicals.

Electrolysis not only oxidizes heavy organic matter, but also:

- Destroys pathogenic biofilms (e.g., Vibrio harveyi),

- Assists in the precipitation of heavy metals through positively charged ions,

- Restores mineralization of the pond substrate.

Read more: The Modern Biosecurity Revolution with Electrolysis Technology

Meanwhile, UV-C light (254 nm) works by damaging the DNA and RNA of pathogenic microorganisms, stopping cellular replication. Can et al. (2023) showed that an integrated UV fine filtration system was able to reduce Vibrio spp. infections by up to 99.9% in just 2 hours of water circulation.

Furthermore, Ahmad et al. (2024) (MDPI – Water) found that UV also triggers natural photocatalytic oxidation, accelerating the degradation of complex organic compounds.

Electrolysis + UV

The combination of these two technologies forms a hybrid system that:

- Increases ORP (Oxidation Reduction Potential),

- Destroys pathogenic biofilm,

Sterilizes water thoroughly without additional chemicals.

Najar-Almanzor et al. (2025) refer to this system as a “smart ecological loop,” in which beneficial microbes are preserved while pathogens are selectively eliminated. In fact, UV-mutagenesis microalgae have been reported to increase nitrogen absorption efficiency by up to 30% compared to natural strains.

Scientifically, this combination forms three layers of ecological defense:

- Biological layer – microbial bioremediation,

- Physical-chemical layer – free radical oxidation,

- Photonic layer – pathogen DNA inactivation.

Partial RAS, Biofloc, and Probiotics: Reducing Waste Load at a Reasonable Cost

The Partial RAS and Partial Biofloc approaches have proven to be more adaptive and cost-effective than fully enclosed RAS systems. These systems have been widely implemented, even in semi-intensive and traditional ponds, such as those in Ecuador.

Common practices include:

- Water recirculation of up to 50% per day,

- Use of treatment ponds for initial oxidation,

- Soft wall biofilters,

- Strong bottom aeration that forms flocs from organic waste.

In traditional systems, the use of natural tides and long canals allows water to undergo a purification process before returning to the pond. Differences in water clarity serve as a visual indicator of the system's success.

Single RAS is not recommended, but a simple combination with electrolysis and UV can reduce the risk of pathogens even at high water flows of up to 500 m³/hour.

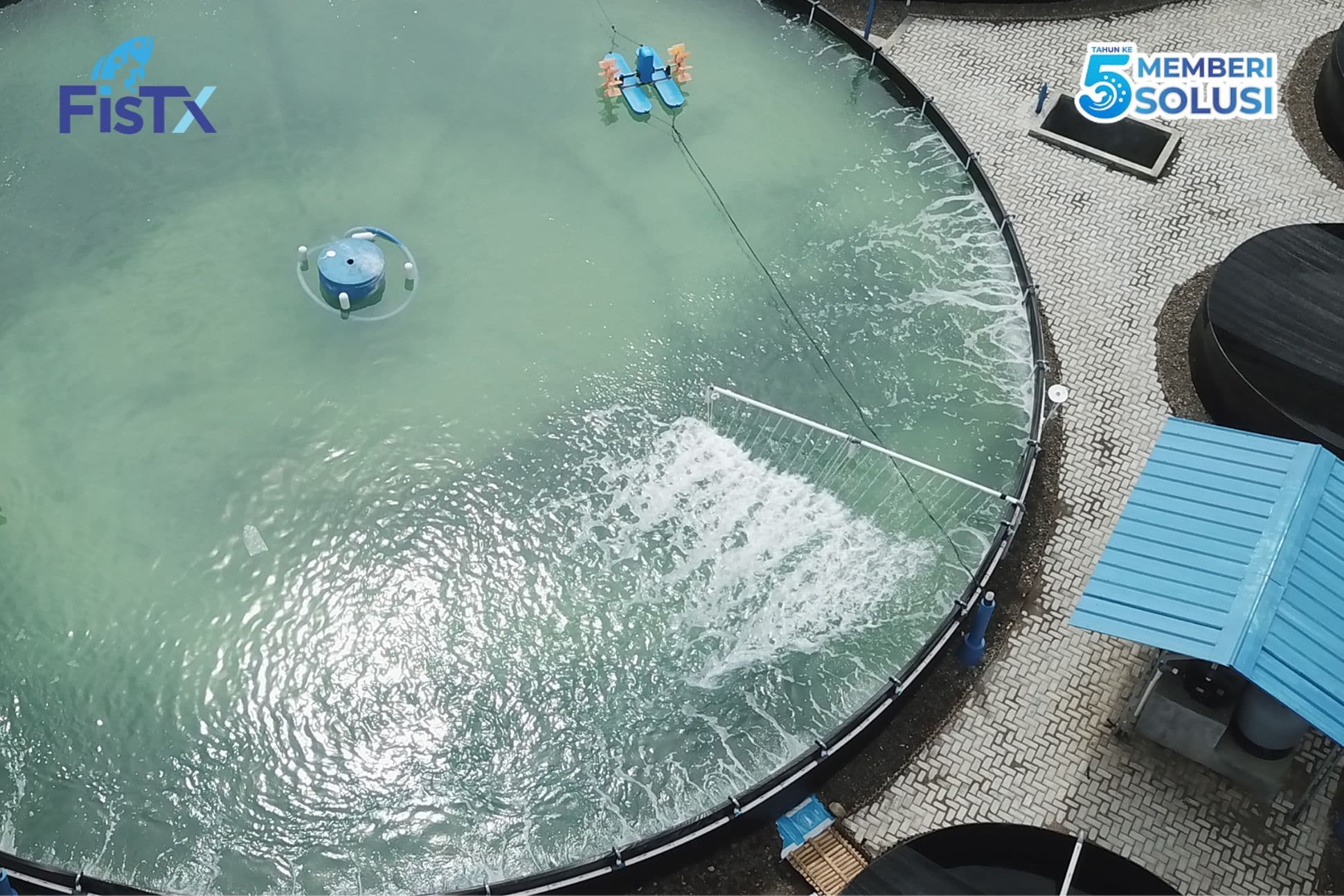

Read more: Round Ponds Are the Answer to the Challenges of Vaname Shrimp Farming

Water Quality Sensors and Automatic Feeders: Rapid Adaptation & Ecological Ethics

Real-time water quality sensors enable farmers to respond quickly to extreme rainfall, pH fluctuations, and DO declines before they reach critical levels. This data forms the basis for precision decision-making, rather than relying solely on intuition.

Meanwhile, automatic feeders play a major role in reducing overfeeding—which has long been considered an “ecological sin” in aquaculture. By feeding based on actual consumption data, the accumulation of organic waste can be significantly reduced.

Maintaining pH and Alkalinity Stability Amid Extreme Weather

Extreme weather fluctuations cause pH and alkalinity instability. Electrolysis technology, active biofilters, and measured ORP management have been proven to help maintain water buffer systems without relying on excessive corrective chemicals.

Zero Water Discharge for Smallholder Fish Farms: Not a Dream

The Zero Water Exchange concept can be implemented through a simple design based on partial RAS and floc. One effective model is:

- grated wastewater treatment pond (equalization, aerobic, anaerobic),

- Sedimentation pond & sand drying bed for solids (used as fertilizer),

- Soft wall biofilter pond,

- Stabilization pond,

- Final stage of electrolysis and UV for disinfection.

This design allows smallholder ponds to improve biosecurity without extreme investment.

The Most Cost-Effective Technology for Productivity & the Ecosystem

In terms of cost and impact, the combination of bioremediation + electrolysis + UV is the most rational choice. The initial investment is relatively affordable, operational costs are low, and the ecological benefits are immediately apparent.

Reducing Dependence on Harsh Chemicals

Nano-disinfection technology (nano silver & nano copper) enables selective disinfection based on stable ORP in the range of 250–350 mV, without toxicity spikes.

Electrolysis precisely produces HOCl and HOBr. HOBr has a short contact time (<2 minutes), is effective against pathogens, is easily biodegradable, and leaves no harmful residues such as THMs commonly found in conventional chlorine use.

Field Evidence: Reviving Abandoned Ponds

In Thailand, Vietnam, and China, a closed system based on RAS & partial floc combined with bioremediation, IMTA, UV, and electrolysis has been proven to restore abandoned ponds and significantly reduce the spread of disease.

Three Key Technologies for 2026

If farmers can only adopt three key technologies, the priorities are:

- Closed systems with measurable productivity,

- IMTA-based bioremediation for aquaculture waste,

- Simple water treatment (electrolysis + UV) as a biosecurity measure.

This combination brings together productivity, climate adaptation, and ecological sustainability—while providing psychological peace of mind for farmers.

The future of aquaculture is no longer determined by how quickly we harvest, but how intelligently we restore ecosystems. Productive and environmentally friendly technologies are not an expensive option, but rather a rational investment in business and environmental sustainability.