The Biosecurity Revolution in Modern Shrimp Farming with Electrolysis Technology

Biosecurity Challenges in Modern Shrimp Farming

In intensive and semi-intensive shrimp farming, water quality is the most crucial factor determining production success. Water not only serves as a living medium, but also as the main route for disease transmission. One of the biggest threats is Vibrio bacteria, such as Vibrio harveyi and Vibrio parahaemolyticus, which are known to be the main causes of EMS (Early Mortality Syndrome).

In systems with high stocking densities and Recirculating Aquaculture Systems (RAS), the risk of pathogen accumulation is greater. If not controlled precisely, this condition can cause a drastic increase in shrimp mortality and significant economic losses.

Limitations of Conventional Chemical Disinfectants

For many years, controlling pond water pathogens has generally relied on chemical disinfectants such as chlorine, iodine, or formalin. However, this method has a number of fundamental weaknesses, including:

- Doses are difficult to control consistently

- Risk of chemical residues in water and cultivated organisms

- Effectiveness decreases when organic content is high

- Operating costs tend to fluctuate

This situation has driven the need for safer, more efficient, and more sustainable water biosecurity technology.

Cakra Elektrolisis: Electrolysis-Based Biosecurity Technology

In response to these challenges, FisTx Indonesia presents Cakra Elektrolisis, an electrochemical water treatment technology specifically designed for modern shrimp farming needs.

Cakra Elektrolisis works by utilizing chloride ions (Cl⁻) that are naturally found in seawater. Through an electrolysis cell with inert catalyst-coated titanium electrodes, this system produces active water directly at the farming site (in-situ generation system), without the addition of external chemicals.

Working Principle of Seawater Electrolysis

In the electrolysis process:

- The anode side produces chlorine gas (Cl₂) which then forms hypochlorous acid (HOCl), a natural oxidizer with a bactericidal power dozens of times more effective than liquid NaOCl.

- The cathode side produces a weakly alkaline catholyte, which helps stabilize the pH and reduce the ammonia content in the water.

The combination of these two processes produces water with high redox potential (ORP), creating a more stable, safe, and pathogen-free cultivation environment.

Smart Biosecurity System for Shrimp Farms

More than just a disinfection tool, Cakra Elektrolisis is designed as a smart biosecurity system. This technology is equipped with:

- Automatic ORP sensor

- Auto-switch and auto-cleaning system

- Precise HOCl output control

- High energy efficiency for long-term operation

The processed seawater will be divided into two main streams, namely active anolyte (HOCl) as the main pathogen control agent, and chlorine to maintain water quality stability. The end result is aquaculture water with high redox activity that supports shrimp health without dependence on additional chemicals.

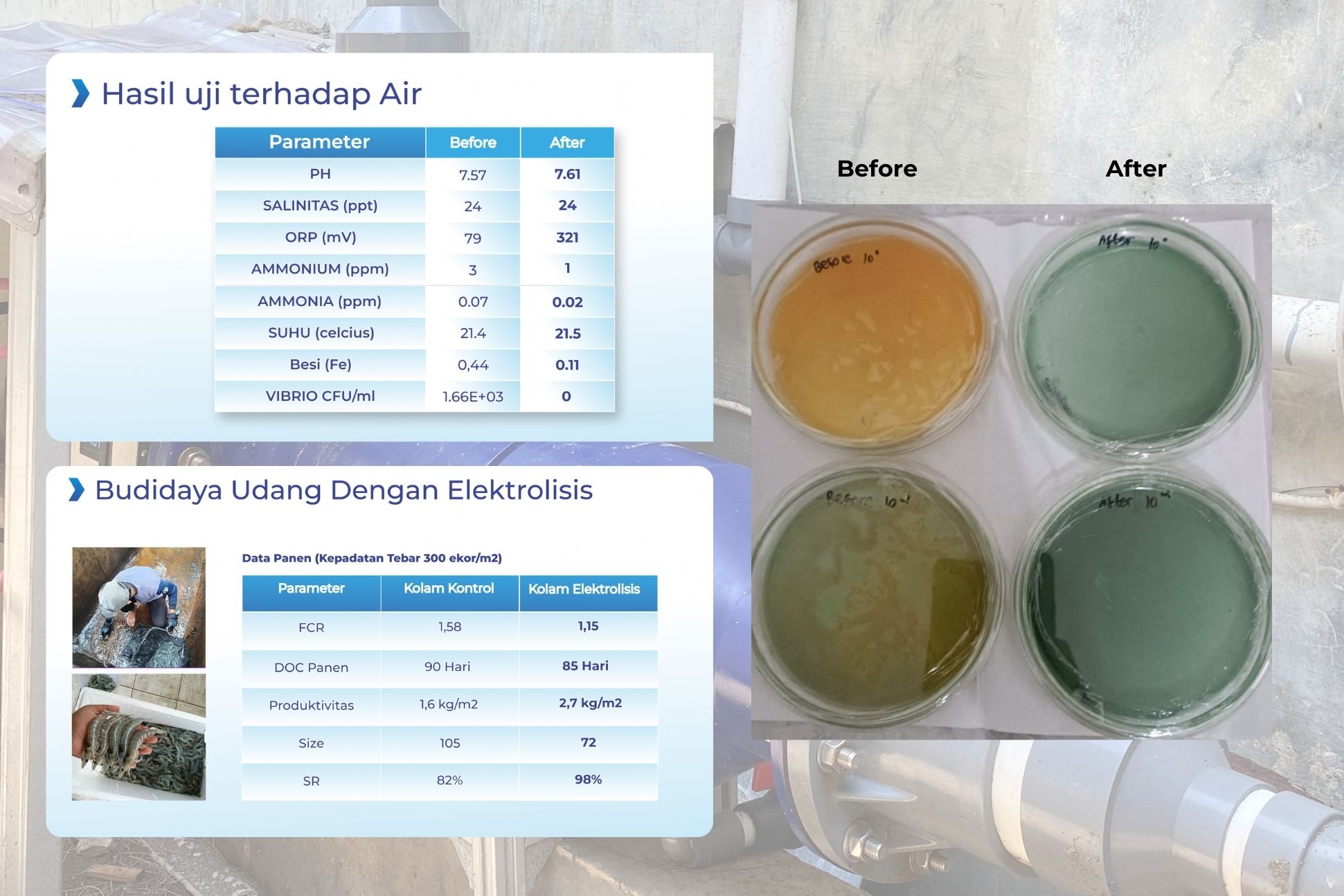

Real Evidence: Field Tests at the Samas Center

The effectiveness of Cakra Elektrolisis has been proven through field trials at the Samas Brackish Water Aquaculture Center, Bantul, during the period July–September 2025. The testing was conducted on 12 aquaculture ponds with the following scheme:

- 6 control ponds using conventional chlorine

- 6 treatment ponds using Cakra Electrolysis + UV on the intake line

Test results showed:

- A reduction in Vibrio population by >99%

- A significant reduction in ammonia and iron levels

- A more stable increase in ORP values

- Improved Feed Conversion Ratio (FCR)

- Increased Survival Rate (SR)

- A drastic reduction in water management costs

As a result, pond productivity increased with significantly lower disease risk.

Water as a Biosecurity Barrier for Fish Farms

These results confirm that water can serve as a biosecurity barrier, rather than a source of threat. With a controlled electrolysis approach, water management becomes more productive, efficient, and sustainable.

FisTx's Cakra Elektrolisis technology proves that modern biosecurity does not have to be expensive and complicated. On the contrary, this technology is a strategic investment to improve production performance, reduce disease risks, and maintain the sustainability of Indonesia's shrimp farming industry.