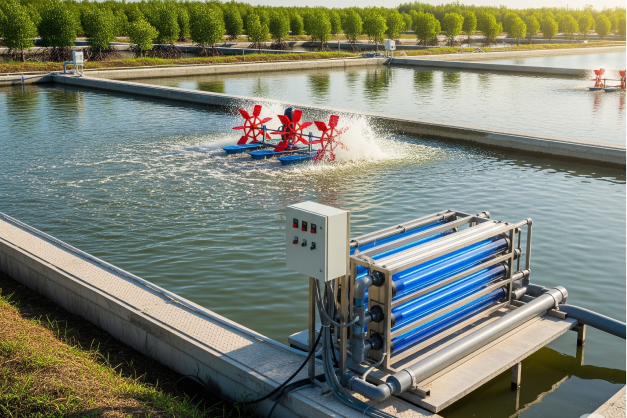

Using a UV System in Your Shrimp Pond, But Still Facing Disease Outbreaks?

The Working Mechanism of UV in Shrimp Ponds for Pathogen Eradication

Ultraviolet (UV) has become a standard technology in modern shrimp pond water disinfection systems. Its working principle is based on the ability of UV-C light (100-280 nm) to induce the formation of thymine dimers in the DNA of microorganisms. When UV in a shrimp pond is active, it eradicates pathogens like Vibrio sp. or the WSSV virus. When exposed to a sufficient UV dose, this genetic damage disrupts replication and gene expression processes, effectively deactivating their infectious capabilities.

However, in practice, many farmers report that their UV systems do not completely prevent disease outbreaks. This phenomenon is often caused by several complex technical and biological factors, ranging from the specifications of the UV equipment used and operational conditions to the natural defense mechanisms of the pathogens themselves. This article will thoroughly explore the technical aspects of using UV in shrimp ponds and provide solutions to optimize its performance.

UV Effectiveness in Shrimp Ponds: Theory vs. Reality

Under controlled laboratory conditions, UV systems in shrimp ponds can achieve >99% inactivation of various aquaculture pathogens. Several studies indicate that a specific UV dose, such as 30 mJ/cm², is sufficient to inactivate most strains of Vibrio parahaemolyticus and White Spot Syndrome Virus (WSSV).

However, in commercial-scale farm applications, many field factors significantly reduce this effectiveness. There are four main reasons why UV use may still be ineffective in shrimp ponds:

1. Lamp Power is Inadequate for Water Volume and Flow Rate

If a small lamp is used for a large or fast water flow, the contact time between the UV light and the water is too short. Consequently, many microbes escape because they are not exposed to sufficient UV radiation.

2. High Water Turbidity/TSS

Water that is too turbid with suspended particles cannot be fully penetrated by UV light across its entire volume. Total Suspended Solids (TSS) above 15 NTU can reduce UV transmission by up to 50%. Colloidal particles in the water act as "shields" for microorganisms, preventing them from being directly exposed to UV light.

3. Incorrect Dosage

Determining the correct UV dose is critical. The dose describes how much UV is exposed to the microbes. If we only provide a UV dose of 10 mJ when a dose of 30 mJ is required to kill the microbes, the UV's effectiveness in eradicating them will be suboptimal.

4. Dirty Lamp Surface (Quartz Sleeve)

UV lamps are protected by a quartz sleeve to prevent direct contact with water. If the sleeve becomes covered in algae or dirt, the UV light cannot penetrate optimally. Biofilm that forms on the quartz sleeve of a UV reactor can reduce its output intensity by up to 90% if not cleaned regularly. (Read also: UV for Shrimp Ponds, What is the Effective Dose to Eradicate Pathogens?)

The Dynamics of UV Intensity and Distance in Aquaculture Systems

The Beer-Lambert Law explains how UV intensity decreases exponentially as it passes through a water medium. Each 1 cm increase in distance from the UV source can reduce intensity by 10-15%, depending on the water's turbidity.

Commonly used low-pressure (LP) UV lamps are indeed highly energy-efficient (30-40%), but they only emit at a single wavelength of 254 nm. In shrimp ponds, a common design flaw is installing the UV reactor with a water flow that is too fast, leading to inadequate retention time. Sufficient retention time and lamp power are necessary to deliver the appropriate UV dose.

Why Do Pathogens Persist Even After Using UV in Shrimp Ponds?

1. Photoreactivation and Dark Repair Mechanisms in Pathogens

Photoreactivation is a phenomenon where microorganisms exposed to UV can repair their DNA damage when subsequently exposed to visible light (300-500 nm). This mechanism is mediated by the photolyase enzyme, which is activated by blue light. In shrimp farming, this process often occurs when UV-treated water is then exposed to sunlight in the cultivation pond.

Furthermore, some pathogenic bacteria possess dark repair mechanisms that do not require light. Enzymatic systems like excision repair and recombinational repair allow for gradual DNA repair.

2. Limitations of Low-Pressure UV Lamps

Low-pressure UV lamps have several structural weaknesses. Their single-wavelength spectrum of 254 nm makes them susceptible to the photoreactivation phenomenon. Additionally, their intensity output is highly dependent on the operating temperature (optimal at 40°C). At cooler pond water temperatures, their effectiveness can drop by 15-20%.

Another issue is performance degradation over time. LP UV lamps typically lose 20-30% of their output intensity after 8,000 hours of operation. If not replaced on time, the delivered UV dose becomes inadequate for pathogen inactivation. Regular measurement of UV intensity with a UV radiometer is highly recommended.

Low-Pressure vs. Medium-Pressure UV

Characteristics of Low-Pressure UV

Low-pressure UV lamps produce monochromatic radiation at 254 nm, which is coincidentally close to the peak absorption wavelength of DNA (265 nm). Their simple design makes them more energy-efficient (30-50% lower electricity consumption than Medium-Pressure UV). However, the weakness of Low-Pressure UV lies in its ability to sterilize water with high turbidity. Water conditions must have a turbidity value below 5 NTU.

In farm applications, Low-Pressure UV is best suited for small-scale recirculation systems with a flow rate of <50 m³/hour. For larger systems, multiple parallel modules are required, which increases installation and maintenance costs. Another weak point is its inability to inactivate some types of viruses that have thick, protective capsid proteins.

Characteristics of Medium-Pressure UV

Medium-pressure UV lamps produce a polychromatic spectrum from 200-400 nm, covering UV-C, UV-B, and parts of UV-A. This broader spectrum offers several advantages:

- The ability to damage not only DNA but also the structural proteins of pathogens.

- A synergistic effect from multiple wavelengths that inhibits the pathogen's cellular repair mechanisms.

- Better penetration in water with moderate turbidity.

Although their energy consumption is higher, their large throughput (up to 500 m³/hour per unit) makes them more economical for large-scale commercial farms.

Why is Medium-Pressure UV More Effective?

There are two main reasons why Medium-Pressure UV is more effective in eradicating pathogens:

1. DNA Sensitivity to Various Wavelengths

Although the peak DNA absorption is at 265 nm, recent research shows that optimal inactivation is achieved with a combination of several wavelengths. UV radiation at 220-230 nm, for example, is effective at breaking the peptide bonds in viral capsid proteins, while the 280-300 nm wavelength helps disrupt cellular repair enzyme systems.

With its broad spectrum, Medium-Pressure UV can deliver a multi-target effect. Research results show that MP UV systems reduce the incidence of WSSV by up to 92% compared to 78% in conventional LP UV systems.

2. Inhibition of Photoreactivation Mechanism

One of the main advantages of Medium-Pressure UV is its ability to reduce photoreactivation. Its combination of wavelengths creates more complex damage to the pathogen's DNA, making it difficult for the photolyase enzyme to repair.

In one study, E.coli strains were irradiated with various UV treatments: 265 nm, 285 nm, and a combination of 265+285 nm. The results showed that the combined 265+285 nm treatment was able to significantly inhibit bacterial photoreactivation. These results explain that UV with a polychromatic spectrum (more than one wavelength) is effective in inhibiting bacterial resurgence.

Application of UV in Shrimp Ponds

1. Optimizing Low-Pressure UV Systems

Low-Pressure UV is a UV light that has a fixed wavelength of 254 nm, also known as monochromatic. This 254 nm wavelength is effective in eradicating pathogens such as bacteria and viruses and is effective for DNA/RNA inactivation. For small farms with limited budgets, LP UV can be more effective if managed correctly:

- Install a multi-stage filter, such as a sand filter, to reduce turbidity/TSS.

- Use a recommended minimum dose of 30 mJ.

- Implement electrolysis before the UV for a Redox (Radiation Oxidation) reaction to ensure more thorough disinfection.

- Besides electrolysis, it can also be optimized with a Nano Disinfectant.

2. Implementing Large-Scale Medium-Pressure UV

Unlike low-pressure UV, Medium-Pressure UV is a UV-C light with a broader spectrum of 200-400 nm. With this wider wavelength, MP UV can eradicate more resistant bacteria and viruses, as well as protozoa and fungi. A broader spectrum allows for much higher pathogen eradication effectiveness. The high speed of pathogen eradication is very suitable for shrimp farming systems that require super-sterile water in a short amount of time.

UV in Shrimp Ponds: An Efficient Solution for Pathogen Control in Modern Shrimp Farming

In modern shrimp farming, disinfection using UV light is increasingly becoming the primary choice for pathogen control. This technology is considered more efficient and environmentally friendly compared to conventional chemical-based sterilization methods. Here are several reasons why UV disinfection is widely chosen:

1. More Cost-Effective Water Sterilization

Using UV lamps can reduce dependency on chemicals in the water sterilization process. Although the initial investment—especially in the first cycle—is quite substantial, the operational costs in subsequent cycles (second, third, and so on) become much more economical. With the correct UV dose, its use can significantly replace the need for chemicals on the farm.

2. Faster Sterilization Time

The UV disinfection process is very fast. When water is exposed to UV light, pathogens immediately suffer DNA damage and die within seconds. The treated water can be used for cultivation immediately, without needing to wait for an oxidation period as required by chemical sterilization, which typically takes 1–2 days. This makes UV highly suitable for farming systems that use water quickly and have high stocking densities.

3. More Land-Efficient

In conventional systems, the water sterilization process requires special reservoirs or ponds that can take up to 40% of the total land area (with a common division: 35% for quarantine and 30% as a reservoir). With UV technology, the need for these reservoirs can be minimized or even eliminated, as the water can be used directly without storage or quarantine. This allows for more optimal land allocation, where 70–80% of the area can be focused on production ponds, with the remainder sufficient for a reservoir.

Want to Apply UV Technology to Your Shrimp Farm?

Using UV in your shrimp pond requires proper planning to maximize results and suppress disease risk. If you are still unsure about determining the right type and capacity of UV for your farm, FisTx is ready to help.

We provide various types of UV that can be customized for small, medium, and large-scale cultivation.

Consult your pond's UV needs now! Contact us at +62 823-2354-5511.