Embracing 2026: 5 Pillar Strategy to Strengthen the National Shrimp Industry to be Globally Competitive

The Indonesian shrimp industry is on the verge of a major transformation. Signs of economic recovery in 2026 bring opportunities as well as new, stricter standards. To win the global competition, industry players can no longer rely on conventional methods. Precise SOP calibration, strengthened monitoring, and the adoption of technology that can reduce operational costs while maintaining quality are needed.

Quoted from Dr. Hasanuddin Atjo's statement via the Metro Sulteng news channel, here are the 5 strategic pillars that will determine the sustainability of Indonesia's shrimp farms in the future:

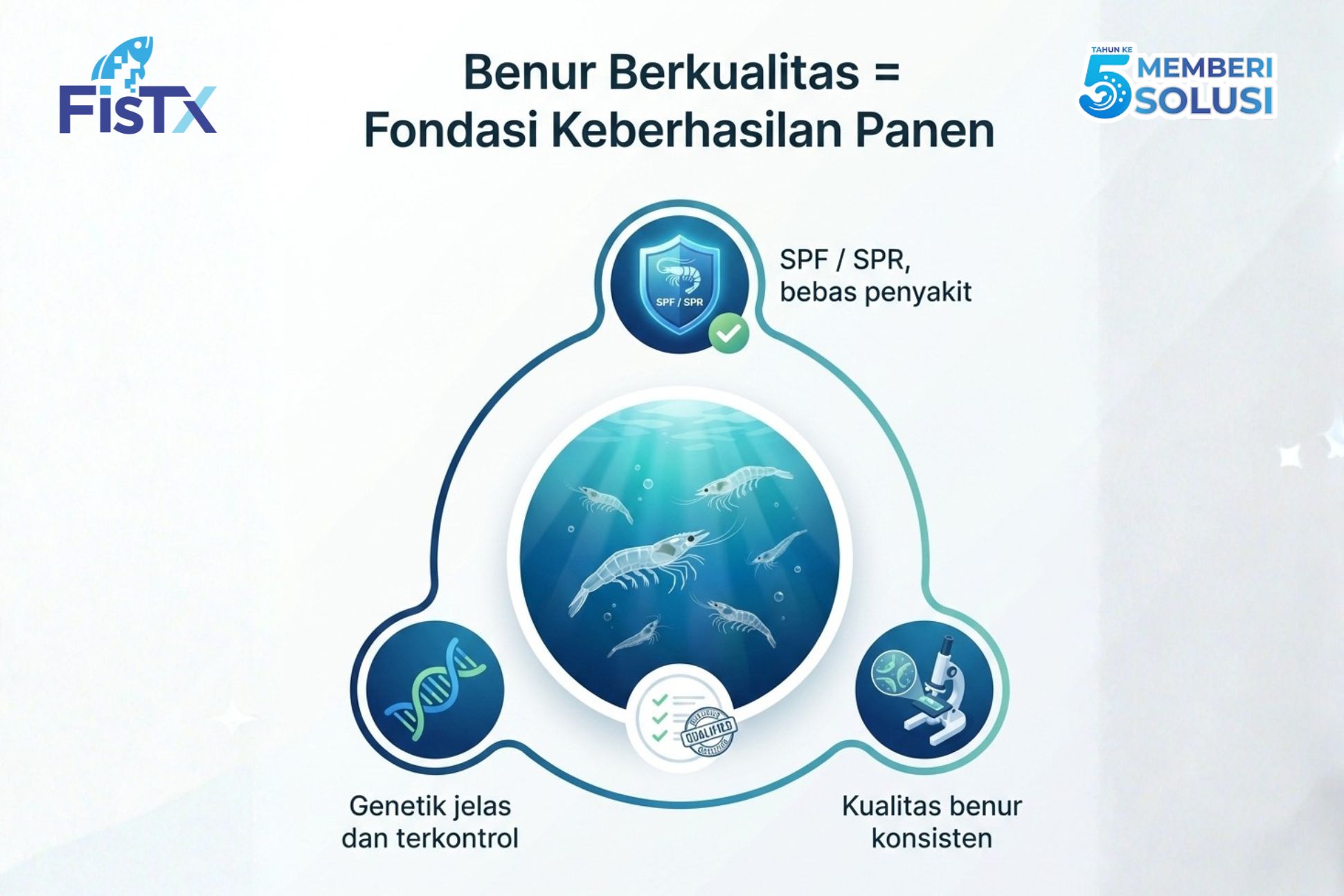

1. Benur: Investment in Genetics and High Quality

The success of the cultivation cycle starts from zero, namely the selection of fry. Many failures in the field today stem from the use of fry with unclear health and genetic conditions.

- SPF/SPR Standardization: Fry must have a Specific Pathogen Free (SPF) certificate.

- Measurable Characteristics: Focus on fry that have fast growth performance and consistent resistance.

- Upstream Monitoring: Calibration of SOPs at the hatchery level is urgently needed to ensure that the fry reaching farmers are of superior quality, in order to reduce production failures early on.

2. Water Sterilization: Transition to Global Market-Friendly Technology

One of the biggest challenges in shrimp exports is the issue of chemical residues. International buyers are now starting to abandon shrimp processed with chlorine or chlorine. FisTx Indonesia has introduced a modern sterilization solution through Cakra Elektrolisis and Baskara UV technology, which is more market-friendly and environmentally friendly.

Cakra Elektrolisis (Eco-Friendly Disinfection): Uses electrochemical oxidation technology to produce high-quality water without chemicals.

- Performance: Capable of reducing 99% of pathogenic bacteria (such as Vibrio) and effectively decomposing ammonia (NH3).

- Cost Efficiency: Compared to chlorine, this system is 89% more economical. Sterilization costs are only around Rp 134/m³, far lower than chlorine, which costs Rp 1,200/m³.

Baskara UV: Utilizes a wavelength of 253.7 nm to instantly eliminate viruses and microbes.

- Durability: High-quality UV-C lamp with a service life of up to 12,000 hours.

- Advantages: Chemical residue-free, maintains stable water parameters, and is highly effective in breaking the chain of disease transmission.

3. Cultivation System: Implementation of Two-Step Nurse

The application of a two-step cultivation system (two-step nursery) is necessary to minimize the risk of disease in grow-out ponds.

- Early Detection: Fry must undergo strict health checks before entering the nursery phase.

- Layered Monitoring: Shrimp must be 100% healthy before being transferred to grow-out ponds. If disease is detected at an early stage, the process must be stopped or managed specifically. This strategy has proven effective in significantly reducing the risk of mass crop failure.

4. Environmental Management: The New Paradigm of IPAL vs. Reservoirs

In the future, waste management will be key to sustainability. The concept of water management must change: The ratio of IPAL area must be greater than that of reservoirs.

- Land Efficiency: Thanks to modern sterilization technologies such as Cakra, which can process high-flow water (up to 200 m³/hour), the land required for storage tanks can be reduced.

- Ecosystem Sustainability: A capable IPAL is the main defense to ensure that wastewater returns to nature in a clean condition, so that surrounding water sources are not damaged and can still be used for long-term cultivation cycles.

5. Post-Harvest Quality: Speed Determines Sales Value

A classic problem in our industry is the decline in shrimp quality during the post-harvest stage. Premium quality shrimp from ponds often lose their value due to slow processing.

- Standardization of SOP: Shrimp must be cooled immediately after being removed from the water, placed in boxes, and sent to the processing plant.

- Avoid Long Sorting: Sorting processes that take too long at room temperature can damage the texture and freshness of shrimp. Maintaining the cold chain is key to maximizing the selling price of shrimp at the factory level.

Conclusion

By 2026, SOP calibration, strengthening data-based monitoring, and adopting environmentally friendly technologies will no longer be optional, but rather an absolute requirement for survival. With technologies such as Cakra Elektrolisis and Baskara UV, farmers will not only be able to produce healthy shrimp, but also achieve remarkable cost efficiencies to compete in the global market.